November 17, 2023

November 17, 2023

Gas turbines play a pivotal role in power generation, aviation, and industrial processes due to their efficiency and reliability. However, ensuring their optimal performance requires meticulous attention to maintenance and environmental considerations. One such crucial aspect is the integration of High-Efficiency Particulate Air (HEPA) filters within gas turbines, marking a significant stride in enhancing their operational efficiency and environmental impact.

HEPA filters are renowned for their exceptional ability to trap minuscule particles with remarkable efficiency, typically capturing 99.97% of particles larger than 0.3 micrometers. In gas turbines, these filters are strategically installed within the air intake system, acting as a robust defense mechanism against contaminants present in the ambient air.

The primary function of HEPA filters in gas turbines is to prevent the ingress of particulate matter that could compromise the turbine's sensitive components. The ingestion of dust, dirt, pollen, and other airborne particles poses a substantial threat to the compressor blades, resulting in erosion, corrosion, and fouling. These issues, if left unaddressed, can significantly diminish the turbine's efficiency and lifespan, leading to increased maintenance costs and reduced operational reliability.

By incorporating HEPA filters, gas turbine operators can mitigate these risks effectively. The filters act as a barrier, intercepting particles before they enter the turbine's internal components. This proactive approach not only safeguards the turbine against potential damage but also contributes to maintaining consistent performance levels over an extended period.

Furthermore, the utilization of HEPA filters in gas turbines aligns with stringent environmental regulations and sustainability goals. By preventing the release of particulate matter and harmful emissions, these filters aid in reducing air pollution, making gas turbine operations more environmentally friendly. This aspect is particularly crucial in sectors like power generation, where minimizing environmental impact is a top priority.

However, while HEPA filters offer substantial advantages, their integration necessitates meticulous planning and periodic maintenance. Regular inspection and replacement schedules are imperative to ensure optimal performance and prevent pressure drop across the filter, which could hamper airflow to the turbine.

In conclusion, the integration of HEPA filters in gas turbines represents a remarkable advancement in enhancing operational efficiency, protecting sensitive components, and reducing environmental impact. Their role in maintaining clean airflow to turbines underscores their significance in ensuring reliable and sustainable operation across various industries. With continued advancements in filtration technology, HEPA filters are poised to play an increasingly pivotal role in optimizing gas turbine performance while fostering a cleaner environment.

Sep. 21, 2023

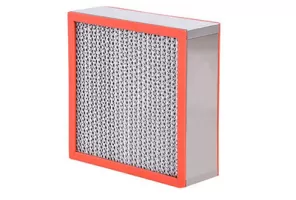

High Temperature H13 Filter ordered by Mexican customer

Sep. 21, 2023

High Temperature H13 Filter ordered by Mexican customer

An order of High Temperature HEPA Filter placed by a US client has been successfully delivered.

Oct. 21, 2024

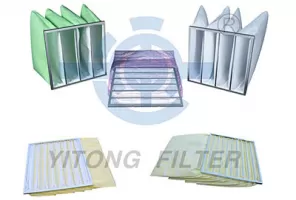

The Ultimate Guide to Pocket Air Filters: What You Need to Know

Oct. 21, 2024

The Ultimate Guide to Pocket Air Filters: What You Need to Know

Mar. 13, 2024

Enhancing Industrial Air Quality: The Versatile Applications of High-Temperature HEPA Filters

Mar. 13, 2024

Enhancing Industrial Air Quality: The Versatile Applications of High-Temperature HEPA Filters