Chemical air filters, often referred to as gas-phase filters or adsorption filters, are specialized air filtration systems designed to remove and neutralize various gaseous pollutants, volatile organic compounds (VOCs), and odorous substances from the air. These filters are commonly used in industrial and commercial settings, as well as in some residential applications, to improve indoor air quality and protect both human health and the environment. Here are some key aspects of chemical air filters:

1. **Adsorption Principle:** Chemical air filters operate on the principle of adsorption, where gaseous contaminants are captured and retained on the surface of an adsorbent material. The most commonly used adsorbents in these filters are activated carbon or activated charcoal.

2. **Removal of Gaseous Pollutants:** Chemical air filters are effective at removing a wide range of gaseous pollutants, including VOCs, odors, smoke, fumes, and chemicals such as formaldehyde, ammonia, and volatile solvents.

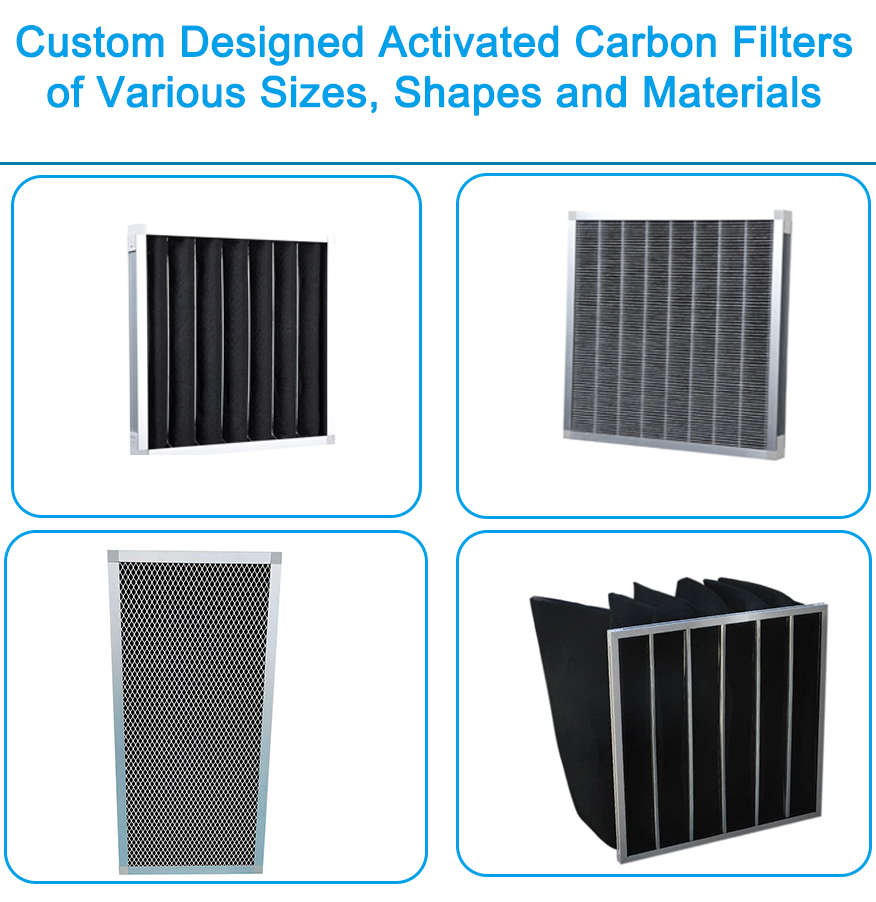

3. **Multiple Contaminant Types:** These filters can be tailored to target specific types of contaminants based on the choice of adsorbent material and the design of the filter. This flexibility makes them suitable for various applications, from industrial settings to residential kitchens and bathrooms.

4. **Activated Carbon:** Activated carbon is the most common adsorbent used in chemical air filters. It has a high surface area with many pores, which allows it to adsorb and retain a variety of gases and odors effectively. The effectiveness of an activated carbon filter depends on the type and quantity of activated carbon used.

5. **Honeycomb or Pellet Beds:** In some cases, activated carbon is used in the form of honeycomb structures or pellet beds to increase the contact surface area and enhance adsorption efficiency.

6. **Activated Alumina and Zeolites:** Besides activated carbon, other adsorbents like activated alumina and zeolites are used to target specific gases and chemicals in certain applications.

7. **Filter Design:** The design of chemical air filters may vary depending on the specific needs of an application. They can be integrated into HVAC systems, air purifiers, or stand-alone units. In some cases, multiple stages of filtration may be used, including pre-filters for particulate removal and chemical filters for gaseous contaminant removal.

8. **Replacement and Maintenance:** Chemical air filters have a finite capacity to adsorb contaminants. Over time, the adsorbent material becomes saturated, and the filter needs replacement or regeneration. Maintenance schedules depend on the type and quantity of contaminants in the environment.

9. **Safety Considerations:** In industrial and laboratory settings, proper handling and disposal of spent chemical air filters are crucial to prevent any contamination risks. Some contaminants may be hazardous and require specialized disposal procedures.

Chemical air filters are essential in various industries, such as chemical manufacturing, laboratories, pharmaceuticals, and commercial kitchens, to ensure a safe and healthy indoor environment. In homes, they are used in air purifiers and other appliances to improve indoor air quality by removing odors and pollutants. When selecting a chemical air filter, it's important to consider the specific contaminants in the environment and choose the appropriate type and size of filter to address the problem effectively.