June 27, 2025

June 27, 2025

An F7 air filter is a medium-to-high efficiency air filter commonly used in HVAC systems to remove fine particles such as dust, pollen, mold spores, and even some bacteria from the air. It belongs to the EN779:2012 classification, which was widely used in Europe before being replaced by the ISO 16890 standard.

If you're looking for cleaner indoor air in commercial buildings, industrial facilities, hospitals, or cleanrooms, F7 filters offer the perfect balance between filtration efficiency and airflow performance.

The term F7 comes from the EN779:2012 standard, which classifies filters based on their ability to capture particles between 0.4 and 1 micron. According to this standard:

F7 filters have an average efficiency of 80-90% for particles in this size range.

They are equivalent to ISO ePM2.5 65-75% in the newer ISO 16890 standard.

This means F7 filters can remove a significant portion of fine dust, allergens, and air pollutants that affect air quality and human health.

Here are the top reasons why F7 air filters are widely used:

1. Efficient Particle Filtration

F7 filters effectively remove fine dust, pollen, and airborne microorganisms, improving indoor air quality and protecting sensitive equipment or occupants.

2. Balanced Airflow and Pressure Drop

Unlike HEPA filters, which can significantly restrict airflow, F7 filters provide excellent filtration with lower pressure drops, helping HVAC systems run more efficiently.

3. Energy Efficiency

Thanks to their moderate resistance and optimized filter media, F7 filters reduce energy consumption, which lowers operating costs over time.

4. Versatile Applications

F7 filters are suitable for a wide range of environments, including:

Commercial buildings

Hospitals and clinics

Data centers

Cleanrooms (as pre-filters)

Food and pharmaceutical industries

Let’s explore where F7 air filters are commonly used:

✅ Commercial HVAC Systems

Used in shopping malls, office buildings, and schools to maintain a healthy indoor environment.

✅ Industrial Ventilation

F7 filters are ideal for manufacturing plants and warehouses where dust and particle control are critical.

✅ Pre-Filters for HEPA Systems

In cleanrooms and healthcare settings, F7 filters are often used as pre-filters to extend the life of HEPA filters.

✅ Air Handling Units (AHUs)

They are commonly installed in AHUs to protect coils, fans, and ductwork from fine dust and particulate buildup.

F7 filters come in various designs and materials to suit different air systems:

| Filter Type | Description |

| Bag (Pocket) Filter | Multiple synthetic fiber pockets that increase surface area and dust holding capacity. |

| Panel Filter | Flat design, compact, and easy to install in tight spaces. |

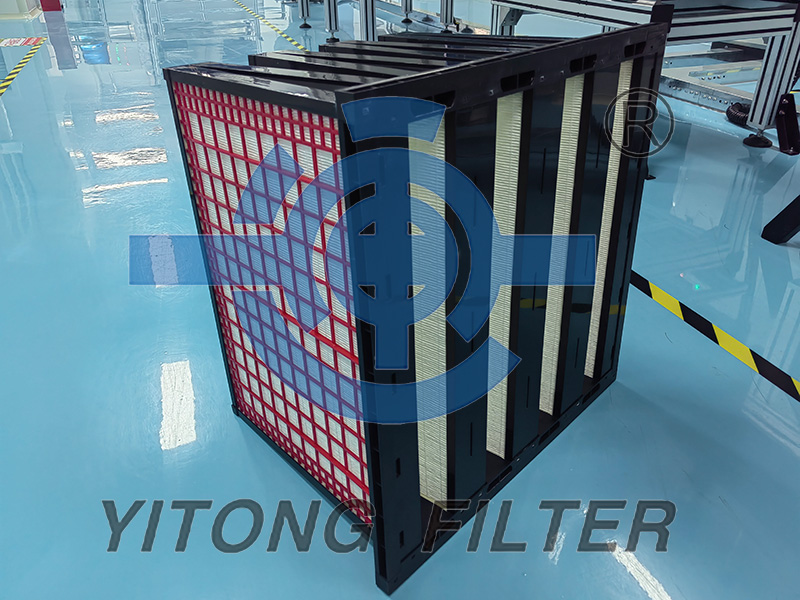

| V-Bank Filter | Rigid plastic frame with V-shaped media for high air volumes. |

| Compact Filter | Space-saving design with high efficiency and low pressure drop. |

When selecting an F7 air filter, consider the following:

✔ Airflow Requirements

Make sure the filter can handle your system’s airflow (measured in CFM or m³/h) without excessive pressure drop.

✔ Operating Conditions

Choose filters with durable materials for environments with high humidity, temperature, or chemical exposure.

✔ Filter Media Type

Synthetic media are more durable and moisture-resistant than fiberglass. Some filters also include antimicrobial coatings.

✔ Dimensions and Fit

Ensure the filter fits perfectly into your HVAC system to avoid bypass leakage or airflow inefficiencies.

✔ Maintenance & Replacement

Check how often the filter needs to be replaced and whether it supports easy maintenance or monitoring.

To maintain optimal performance:

Inspect filters every 1–3 months, depending on environment and usage.

Replace filters when pressure drop increases significantly or at the recommended interval (usually 3–6 months).

Avoid reusing disposable filters.

Consider differential pressure sensors for automated monitoring in sensitive applications.

| Filter Type | Efficiency | Common Use |

| M5 (ISO ePM10) | ~40-60% | Basic dust control |

| F7 (ISO ePM2.5) | ~65-75% | General-purpose fine particle removal |

| F9 (ISO ePM1) | ~80-90% | High-efficiency pre-filtration |

| H13 HEPA | ≥99.95% (0.3 μm) | Cleanrooms, surgical suites, labs |

If you're looking for a high-performing air filter that offers solid protection against fine dust and allergens without overloading your HVAC system, an F7 air filter is an excellent choice. It’s energy-efficient, affordable, and suitable for most commercial and industrial applications.

Whether you’re upgrading your building's ventilation or designing a multi-stage filtration system, F7 filters provide a reliable balance between performance and cost.

If you need help selecting the right F7 filter for your specific application, feel free to contact our air filtration experts today!