October 23, 2025

October 23, 2025

Cleanrooms are critical environments where even a tiny particle can ruin a process or contaminate a product. Whether used in pharmaceuticals, electronics, biotechnology, or aerospace industries, cleanrooms rely on one key component to maintain purity — HEPA filters.

In this article, we’ll explain what cleanroom HEPA filters are, how they work, their types and classifications, and why they’re essential for maintaining a contamination-free environment.

A HEPA (High-Efficiency Particulate Air) filter is designed to capture microscopic particles that standard air filters cannot. For cleanrooms, HEPA filters are specially engineered to meet strict air quality standards.

According to international standards, a true HEPA filter must remove at least 99.97% of particles as small as 0.3 microns. These include dust, bacteria, mold spores, and even aerosolized viruses.

In cleanroom applications, HEPA filters are installed in terminal housings, fan filter units (FFUs), or air handling systems to ensure that only purified air enters the controlled space.

Cleanroom environments are classified by their allowable particle concentration per cubic meter of air (ISO 14644-1 standards). For instance:

ISO Class 5: Maximum 3,520 particles (≥0.5 μm)

ISO Class 7: Maximum 352,000 particles (≥0.5 μm)

Without HEPA filters, it would be impossible to achieve these cleanliness levels. Here’s why they matter:

1. Particle Control – Removes 99.97% of fine particles that can damage semiconductors or contaminate sterile drugs.

2. Product Quality – Ensures that sensitive manufacturing processes remain defect-free.

3. Personnel Safety – Protects workers from exposure to hazardous aerosols.

4. Regulatory Compliance – Meets cleanroom standards required by FDA, ISO, or GMP.

HEPA filters capture particles using several physical mechanisms:

Interception – When particles follow airflow and touch a fiber, they stick.

Impaction – Larger particles collide directly with fibers and are trapped.

Diffusion – Small particles move randomly (Brownian motion) and eventually hit and stick to fibers.

This multi-layered trapping process allows HEPA filters to efficiently capture particles of various sizes — including the most penetrating particle size (MPPS) around 0.3 microns.

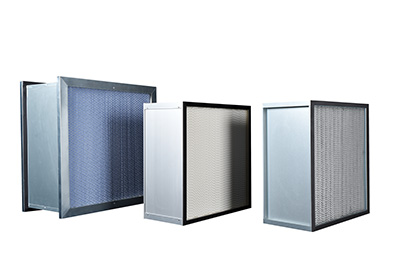

Not all HEPA filters are the same. Depending on design and application, they come in several types:

1. Mini-Pleat HEPA Filters

Compact design with closely spaced pleats, ideal for FFUs and limited-space environments.

2. Separator HEPA Filters

Include aluminum separators for high airflow and long service life.

3. Gel Seal HEPA Filters

Use gel seals for a leak-free connection with filter frames, ensuring zero bypass.

4. Box-Type HEPA Filters

Commonly used in HVAC systems and cleanroom ceilings, easy to install and replace.

Each type is selected based on airflow rate, pressure drop, and cleanliness class requirements.

HEPA filters are classified under EN 1822 or ISO 29463 standards. Common grades include:

H13 – ≥99.95% efficiency (EU standard)

H14 – ≥99.995% efficiency

U15 / U16 – Ultra-high efficiency for the most sensitive cleanrooms

For most cleanroom environments, H14 filters are preferred because they balance efficiency and airflow resistance.

Cleanroom HEPA filters are used across various industries:

Pharmaceuticals – To prevent cross-contamination in sterile manufacturing areas.

Semiconductors & Electronics – To avoid micro-particle damage during chip fabrication.

Biotechnology – To maintain sterile conditions for biological experiments.

Aerospace & Optics – To ensure dust-free environments for precision assembly.

Hospitals & Laboratories – To create contamination-free zones in operating rooms or biosafety cabinets.

Proper installation and maintenance are vital to ensure consistent performance.

1. Integrity Testing – Perform leak tests (like DOP or PAO tests) after installation to verify filter efficiency.

2. Pre-Filtration – Use pre-filters to capture larger particles and extend HEPA lifespan.

3. Pressure Monitoring – Regularly check pressure drop across filters; rising pressure means it’s time to replace.

4. Clean Environment – Install filters only in a dust-free area to prevent contamination during assembly.

Typically, HEPA filters last 1 to 3 years, depending on the cleanliness of the air supply and operating conditions.

HEPA vs. ULPA Filters

Sometimes, ultra-clean applications require ULPA (Ultra-Low Penetration Air) filters. These filters can remove 99.9995% of particles down to 0.12 microns.

However, ULPA filters also create higher airflow resistance and energy consumption, making HEPA filters a more practical choice for most cleanrooms.

Cleanroom HEPA filters are the heart of contamination control. They keep the air ultra-clean, protect sensitive products, and ensure compliance with ISO and GMP standards.

By choosing the right HEPA grade, maintaining proper installation, and performing regular testing, cleanroom operators can achieve stable performance and product quality over time.

Whether you are designing a new cleanroom or upgrading your filtration system, investing in high-quality HEPA filters is one of the smartest decisions you can make for safety, efficiency, and long-term reliability.