October 15, 2025

October 15, 2025

Gas turbines and turbomachinery are critical components in power generation, aviation, and industrial applications. Their performance and reliability depend heavily on the quality of the air entering the system. Dust, salt, and other airborne contaminants can erode turbine blades, reduce efficiency, and increase maintenance costs.

That’s why air filtration systems—especially compact V-bank filters—play such a crucial role in protecting these high-value assets.

This article explores what compact filters (V-bank filters) are, how they work, their advantages, and why they are widely used in gas turbine and turbomachinery air inlet systems.

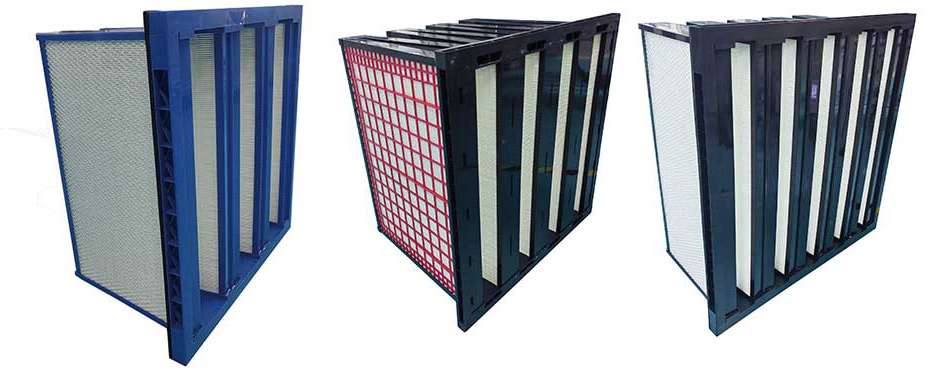

Compact filters, also known as V-bank filters or mini-pleat filters, are high-efficiency air filters designed for demanding environments. They feature a unique V-shaped configuration that maximizes filter surface area while maintaining a compact size.

The V-bank design typically includes multiple pleated filter media arranged in a V-shaped frame—usually four, six, or eight V-shaped channels. This structure allows for:

Higher dust-holding capacity

Lower pressure drop

Longer service life

V-bank filters are often used as the final filtration stage in gas turbine air inlet systems, where both high efficiency and durability are essential.

In gas turbine air inlet systems, the filtration process usually has multiple stages:

1. Coalescer or pre-filter stage – removes larger particles and moisture.

2. Intermediate filter stage – captures smaller dust and fine aerosols.

3. Final filter stage (Compact V-Bank Filter) – ensures that only clean, dry air reaches the turbine compressor.

The V-bank filter uses pleated synthetic or fiberglass media arranged in a V-configuration. As the contaminated air passes through, the media traps microscopic particles such as:

Dust

Pollen

Salt crystals

Industrial pollutants

This clean air then enters the turbine compressor, ensuring smooth operation and protecting internal components from fouling and erosion.

1. High Filtration Efficiency

V-bank filters are available in various efficiency ratings—typically MERV 13 to 16, or EPA E10 to E12, depending on system requirements. They can effectively capture fine dust and salt particles that can otherwise cause turbine degradation.

2. Compact Design

Their V-shaped configuration offers a large filtration area within a compact frame. This means:

Smaller installation space

Lightweight construction

Easier retrofit into existing systems

3. Low Pressure Drop

The increased surface area ensures a low and stable pressure drop, improving airflow and reducing energy consumption by the turbine or fan.

4. Long Service Life

Thanks to their high dust-holding capacity, V-bank filters last longer than traditional box or bag filters, reducing maintenance frequency and total cost of ownership.

5. Moisture and Corrosion Resistance

Many compact filters for gas turbines use hydrophobic synthetic media and plastic or metal frames that resist corrosion, even in coastal or humid environments.

V-bank filters are built from durable, high-performance materials to withstand challenging conditions:

| Component | Common Material | Function |

|---|---|---|

| Filter Media | Synthetic fiber, fiberglass, or nanofiber | Traps fine dust and salt particles |

| Frame | Plastic (ABS, polypropylene) or galvanized steel | Provides structural stability |

| Sealant | Polyurethane or hot-melt adhesive | Ensures leak-free construction |

| Gasket | EPDM or neoprene foam | Provides an airtight seal in the filter housing |

Each component is selected to ensure long-term performance, even under high airflow, vibration, and temperature variations.

Compact (V-bank) filters are used across various industrial and energy sectors, including:

Power generation – protecting heavy-duty gas turbines in power plants.

Oil and gas – maintaining clean air intake for offshore and onshore turbine units.

Petrochemical plants – filtering process air in corrosive or dusty environments.

Aviation ground power units – ensuring clean airflow for turbine efficiency.

Industrial air compressors and blowers – improving machinery longevity.

Their compact structure and high performance make them ideal for both retrofit and new installations in these high-demand applications.

1. Improved Turbine Efficiency

Clean air intake reduces fouling of compressor blades, maintaining the aerodynamic profile and efficiency of the turbine. This leads to better fuel economy and higher power output.

2. Reduced Maintenance Costs

Long filter life and reliable performance minimize the need for frequent replacements, reducing downtime and labor costs.

3. Enhanced Equipment Protection

By preventing dust, salt, and other contaminants from entering the compressor, V-bank filters help extend the life of turbine blades and seals.

4. Stable Operation in Harsh Environments

Compact filters perform reliably in environments with high humidity, desert dust, or salt-laden air, maintaining efficiency under tough conditions.

5. Energy Savings

A lower pressure drop means the turbine or blower requires less energy to draw air through the filter—helping reduce operational energy consumption.

When selecting a V-bank filter for gas turbine use, engineers often evaluate:

| Parameter | Typical Range | Description |

|---|---|---|

| Efficiency | MERV 13–16 / E10–E12 | Defines particle capture rate |

| Pressure Drop | 150–250 Pa | Resistance to airflow |

| Airflow Capacity | Up to 3400 m³/h | Amount of air the filter can handle |

| Dust Holding Capacity | Up to 2000 g | Indicates filter longevity |

| Temperature Resistance | Up to 80°C | Maximum operating temperature |

Choosing the right balance of efficiency and pressure drop ensures optimal turbine performance and filter longevity.

| Feature | Compact (V-Bank) Filter | Panel or Bag Filter |

|---|---|---|

| Surface Area | Very high | Moderate |

| Pressure Drop | Low | Higher |

| Service Life | Long | Shorter |

| Maintenance Frequency | Low | Frequent |

| Installation Space | Compact | Larger |

| Typical Application | Final filtration stage | Pre- or medium filtration |

V-bank filters outperform traditional filter designs in high-performance turbomachinery systems due to their optimized structure and longer life cycle.

To ensure the best performance, proper installation and maintenance are essential:

1. Check air flow direction – Install the filter in the correct orientation.

2. Inspect gaskets and seals – Ensure no bypass leakage.

3. Monitor pressure drop – Replace the filter when differential pressure exceeds the manufacturer’s recommendation.

4. Avoid moisture accumulation – Prevent water ingress in the filter housing.

5. Use compatible pre-filters – To extend the lifespan of the V-bank filter.

Regular monitoring and timely replacement help maintain system efficiency and protect turbine components.

Modern compact filters are often fully incinerable or made with recyclable materials, supporting sustainable maintenance practices.

Longer service life means fewer filter replacements and less waste—helping operators reduce both environmental impact and operational costs.

Compact filters (V-bank filters) have become the industry standard for protecting gas turbines and turbomachinery. Their advanced design delivers high efficiency, low pressure drop, and long service life—key factors in maintaining reliable performance and minimizing operational costs.

By investing in quality V-bank filters, turbine operators can ensure cleaner air, improved efficiency, reduced maintenance, and a longer equipment lifespan.

Whether you operate a power plant, refinery, or industrial compressor station, compact V-bank filters offer a proven, cost-effective solution for achieving optimal turbine protection and sustainable operation.