Pleated membrane cartridge filter made from different micro-membranes with big filter area, high flow, high dirty holding capacity, etc. Our products meet the requirements of FDA and GMP, which widely used in food industry and pharma industry.

Our workshop

100,000-level industrial cleanroom: 2,000 ㎡

CNC pleating machine with full-auto feeding system: zero damage

Infrared bonding machines

Quality control

Pore size analysis and detection before processing

100% integrity test for sterilizing grade filter

Pure water cleaning

Authentication service preferred

Application

Pre-filter of water system, sterile filtration, process filtration of pharma industry and food industry, Sterilization and filtration of industrial gases.

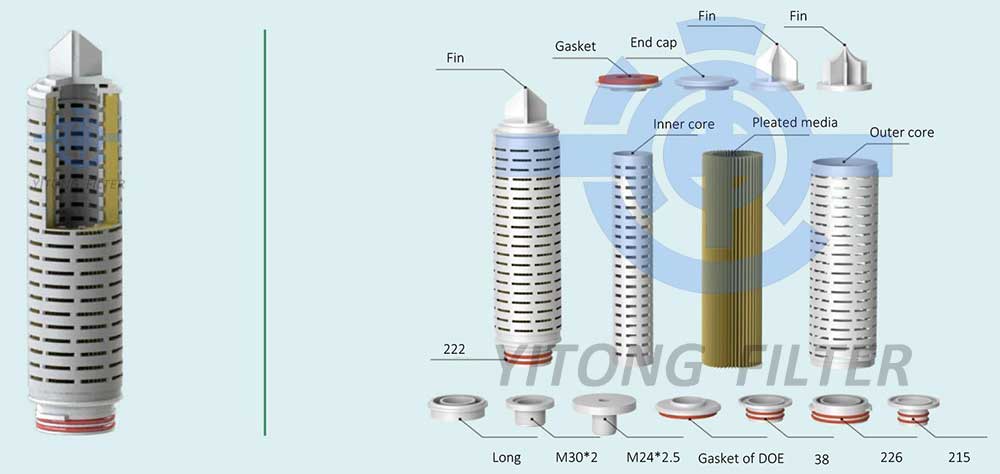

Micron Pleated Filter Cartridge Structure

| Product information | |

| Inner / outer core | PP / PFT / PTEF / PVDF |

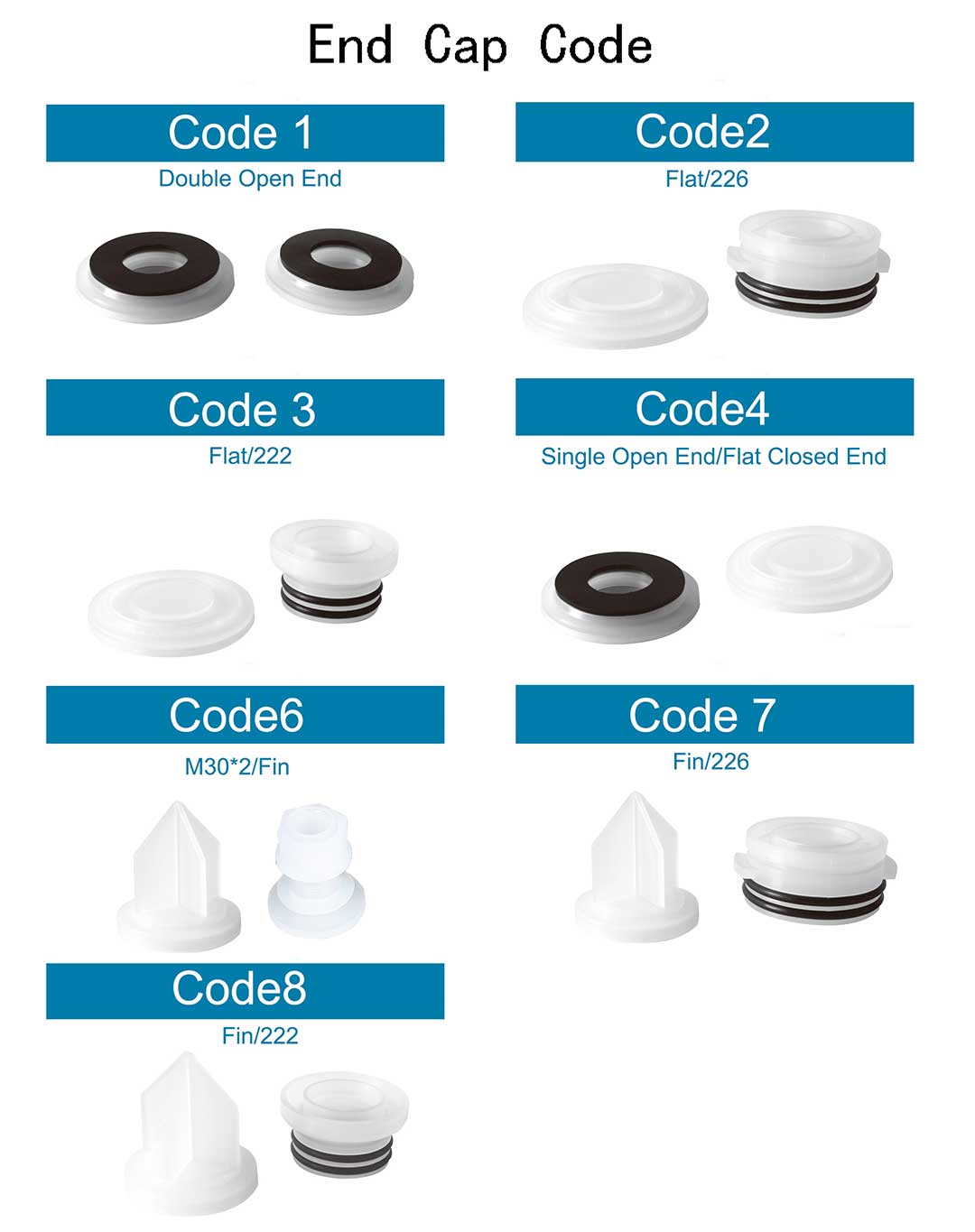

| End type | Bayonet / Fin |

| Filter membrane | PP/PVDF/PTEE/NL/GF/PET |

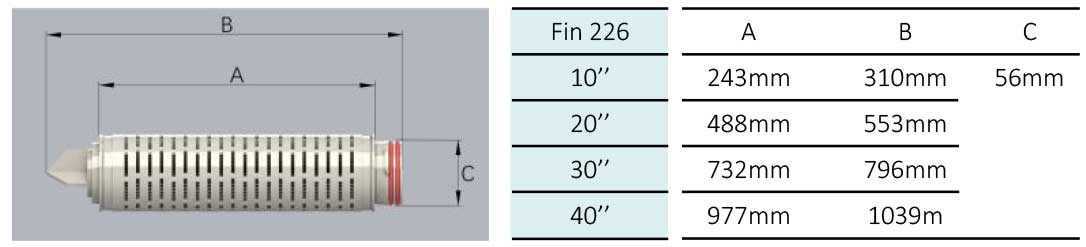

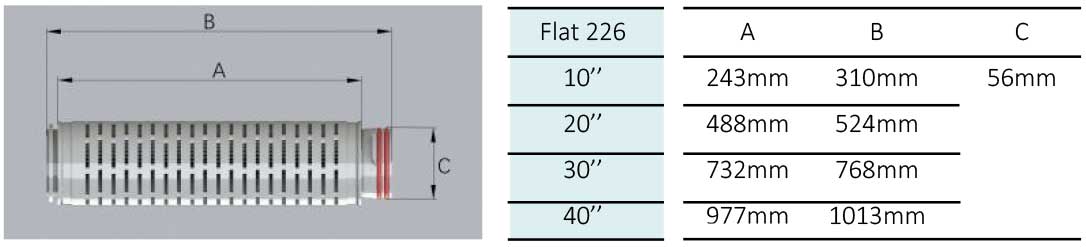

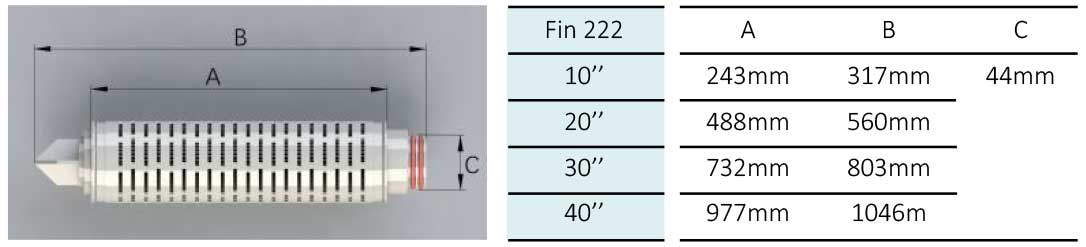

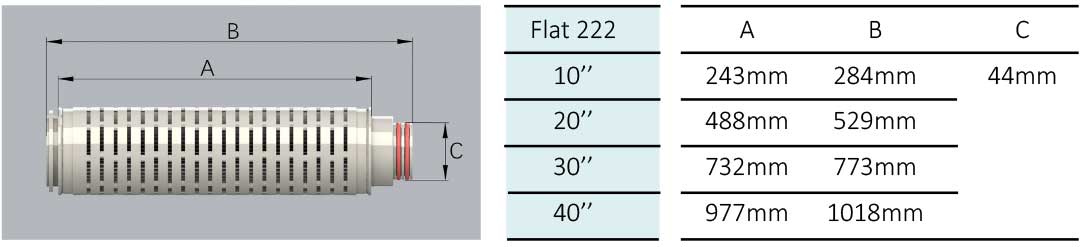

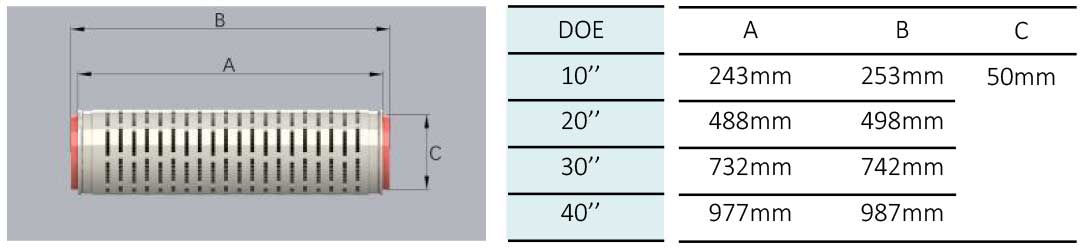

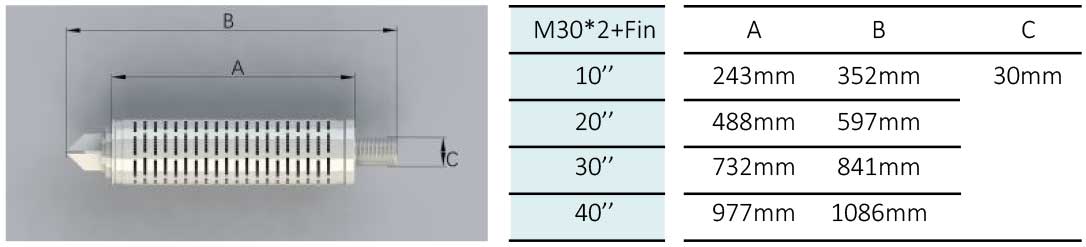

| Adapter | 215 / 220 / flat 222 / high 222 / 226 / DOE |

| Ring | Silicone / EPDM / NBR / Viton / Teflon / E-FKM |

| Support layer | PP/PET / PTFE / PP net |