June 27, 2023

June 27, 2023

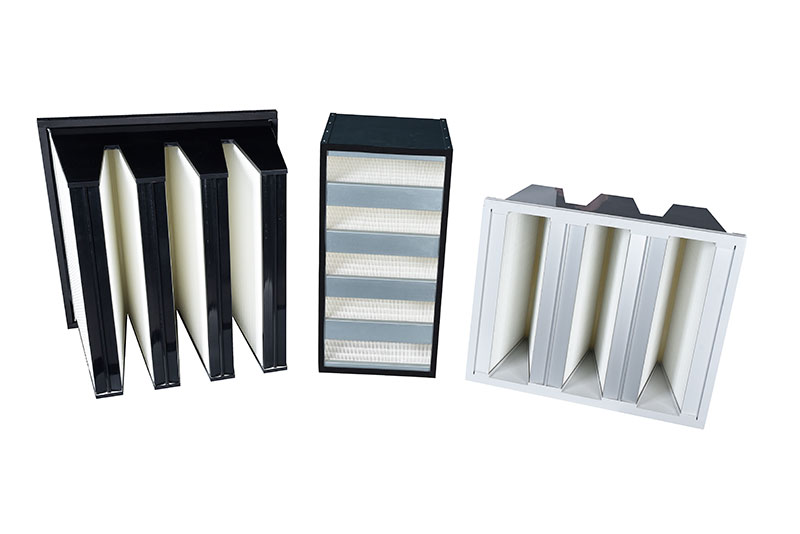

V-Bank type air filters, also known as FV combination air filters, are composed of multiple unpartitioned filter cores in a W-shaped structure. They are made and installed in galvanized steel plates or polypropylene plastic frames. Compared to regular filters, the combination air filter greatly increases the number of filter materials, ensuring lower pressure loss, thereby reducing energy consumption and saving operational costs.

The FV combination sub-efficient filter ensures that it is not corroded in high-humidity environments. The FV combination sub-efficient filter is designed with an airflow capacity of up to 4000m3/h. With a depth of only 292mm, it is suitable for ventilation and air conditioning systems with limited installation space.

Classification of V-type air filters:

They can be classified into 3V air filters, 4V air filters, and 5V air filters based on their shapes.

Design features of V-type air filters:

High-quality ultrafine glass fiber filter paper or PP filter material

Non-toxic gas pollution during incineration

Large filter area, low resistance, long service life for FV combination sub-efficient filters

With a depth of only 292mm, the FV combination sub-efficient filter is suitable for ventilation and air conditioning systems with limited installation space

Equipped with a flange frame, it can be interchanged with commonly used bag filters.

W-shaped V-type combination efficient filters are divided into two types: flanged FV combination sub-efficient filters and non-flanged FV combination sub-efficient filters. Please specify the type when purchasing.

General principles for selecting filters:

Inlet and outlet diameter: Ideally, the inlet and outlet diameter of the filter should not be smaller than the inlet diameter of the corresponding pump and generally should be the same as the inlet pipe diameter.

Nominal pressure: Determine the pressure level of the filter based on the highest pressure that may occur in the filtering pipeline.

Attached are the relevant standards for the replacement cycle of middle and high-efficiency filters:

If the resistance of the coarse filter exceeds the rated initial resistance by 60Pa or equals 2 times the design or operational initial resistance, it should be replaced every 3-6 months. If it exceeds the standard, it should be replaced immediately. Clean the coarse filter, F7 grade bag medium-efficiency filter, and return air outlet device once a week.

Replace the pre-filter and F8 grade bag medium-efficiency filter at most every 6 months. Replace the high-efficiency filter annually. If the resistance of the medium-efficiency filter exceeds the rated initial resistance by 80Pa or equals 2 times the design or operational initial resistance, it should be replaced every 6-12 months. If it exceeds the standard, it should be replaced immediately.

If the resistance of the sub-efficient filter exceeds the rated initial resistance by 100Pa or equals 2 times the design or operational initial resistance, it should be replaced after one year. If it exceeds the standard, it should be replaced immediately.

If the resistance of the high-efficiency filter exceeds the rated initial resistance by 160Pa or equals 2 times the design or operational initial resistance, it should be replaced after two years. If it exceeds the standard, it should be replaced immediately.

Nov. 21, 2023

The Application of Air Filters in HVAC Systems

Nov. 21, 2023

The Application of Air Filters in HVAC Systems

May. 29, 2024

Pocket Air Filters: A Comprehensive Guide

May. 29, 2024

Pocket Air Filters: A Comprehensive Guide

Aug. 09, 2023

Differences between F8 and F6 Medium Efficiency Filters

Aug. 09, 2023

Differences between F8 and F6 Medium Efficiency Filters